Conductive foam is a conductive preparation sleeve wrapped around the use of polyurethane or EPDM composition of the foam core, conductive preparation sleeve is usually composed of silver-plated nickel nylon, aluminum berth, or Monel wire (nickel-copper alloy) Ferrex (tinned copper-coated steel wire), has good electrical conductivity. Conforms to the flame retardant grade (UL94-V0), with good elasticity flexibility and other mechanical properties.

Conductive foam has good shielding properties, when encountered with electric waves, it will be according to the nature of the object and reflect, absorb, and provide excellent shielding effect. The flame retardant sponge is wrapped in conductive cloth, after a series of processing, so that the conductive foam has a good surface conductivity, and can be easily fixed with adhesive tape in the need to shield the device. Foam has different profile shapes, installation methods, UL ratings, and shielding effectiveness of the shielding material available.

The use of conductive foam so much, in the face of a variety of products on the market, how do we choose? How to determine whether the conductive foam is qualified? Here we summarize some of the methods of testing conductive foam:

The surface of the conductive cloth or aluminum foil cloth is smooth and without damage; there is no obvious print crease or defect on the surface to the naked eye.

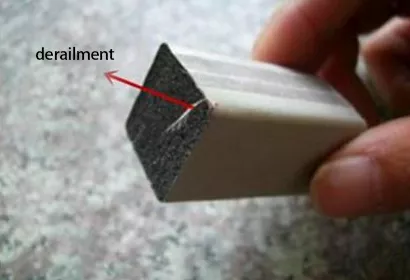

Neatly cut all around, with no threading phenomenon.

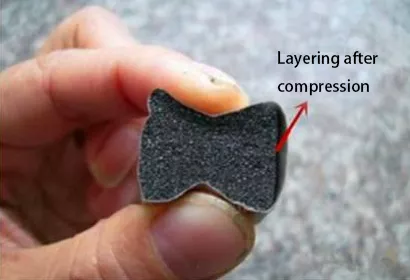

Hand pinch the conductive foam, compressed to about 2/3 of its height or thickness, there is no sponge and conductive cloth (aluminum foil cloth) separation

The surface of the double-sided adhesive pasted on the conductive foam must be flat and free of wrinkles and lack of adhesive.