Electrical shielding is used to prevent interference with components due to high voltage field strengths. The design principle of electrical shielding is to minimize the distributed capacitance between the interference source and the receptor by using the shield to minimize the effect of the interference source on the receptor.

Electrical shielding materials are various materials used between heat sources and heat sinks to accelerate heat dissipation efficiency by excluding the air between heat sources and heat sinks, thus making the heat of electronic devices more evenly dispersed. Generally, various thermally conductive interface materials need to have good thermal conductivity and surface wettability.

Conductive adhesive: a class of adhesives with conductive properties, conductive adhesive is a cured or dried with certain conductive properties of the adhesive, it is usually based on the base resin and conductive filler that is conductive particles as the main component, through the adhesive effect of the base resin to the conductive particles are combined to form a conductive pathway to achieve a conductive connection of the bonded material.

As the basic resin of the conductive adhesive is an adhesive, you can choose the appropriate curing temperature for bonding, and at the same time, due to the miniaturization of electronic components, miniaturization, and printed circuit boards, high density and highly integrated rapid development, and the conductive adhesive can be made into a paste, to achieve a very high line resolution. And conductive adhesive process is simple, easy to operate, and can improve production efficiency, so the conductive adhesive is an alternative to lead and tin soldering, to achieve the ideal choice of conductive connection.

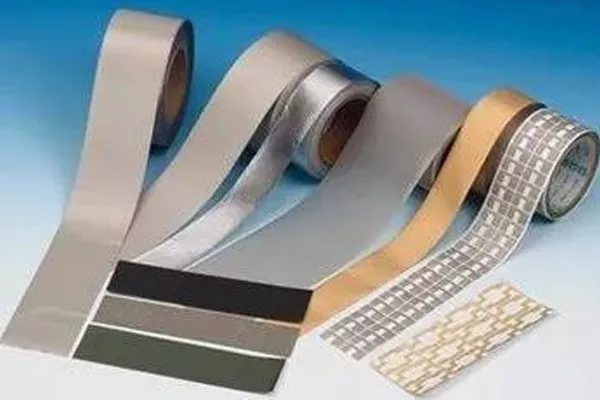

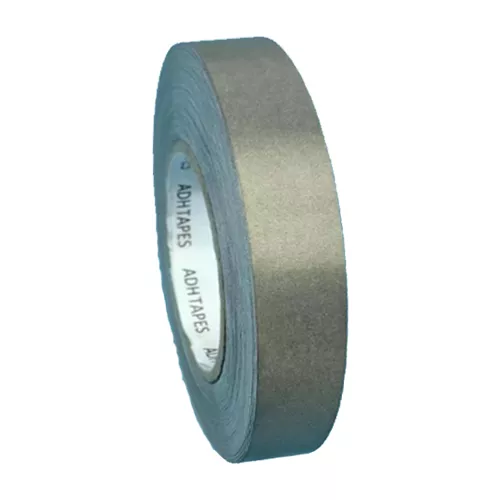

Conductive shielding materials are mainly conductive foam, conductive cloth, conductive double-sided tape, copper foil, aluminum foil, and wave-absorbing materials. The following is to understand the use of these series:

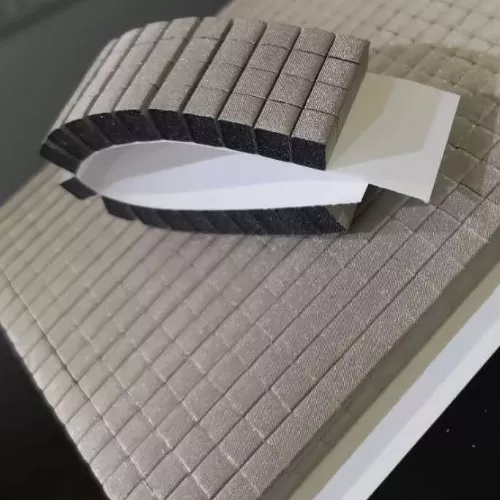

Omni-directional conductive foam

Conductive cloth is mainly divided into plaid-type conductive cloth and knitted conductive cloth. Lattice cloth has good conductivity, good shielding effect, and good processability, suitable for wrapping into various types of rules and irregular common conductive foam preferred material, mainly for ultra-thin shielding, conductive cloth foam, conductive cloth tape, conductive cloth liner, etc., with good friction resistance. Knitted conductive cloth has good anti-friction properties, is easy to stamp and process molding after wrapping, low-cost easy to wrap the molding nature of the I / O liner preferred material.

Conductive cloth: As the conductive cloth is highly metalized nylon or polyester material substrate, with excellent conductive properties equivalent to metal, at the same time there is good toughness and can be wound performance, back conductive adhesive is a variety of electronic and electrical appliances and communications equipment shielding the ideal material, at the same time on the circuit board or a variety of surfaces of the shielding and grounding is also very suitable.

Characteristics of lattice-type conductive cloth:

Knitted conductive fabric features: