+86-755-2301-3143

Conductive Tapes | Foams | Sponges

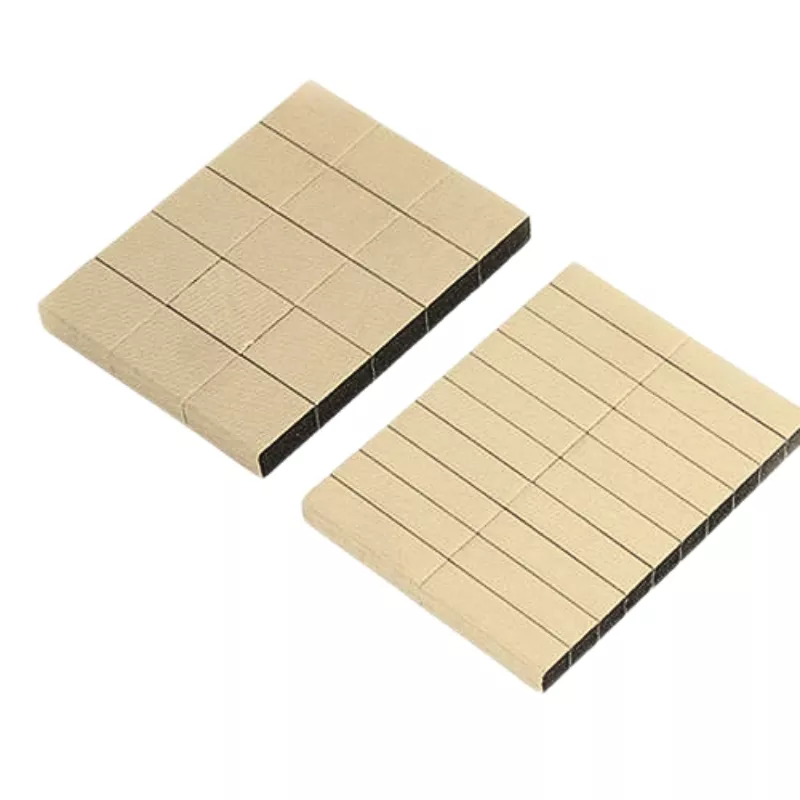

Foam Conductive Tape is a specialized adhesive product that combines the advantages of foam materials with conductive properties. It is typically made by infusing or coating a foam base, such as polyurethane or polyethylene foam, with conductive substances like carbon black, silver - coated particles, or metal - filled polymers. This unique combination results in a tape that not only offers the softness, cushioning, and conformability of foam but also the electrical conductivity required for specific applications.